The upper section of the steel body features threading to attach the drilling tool, while the lower section is sintered onto the body. The steel body can be crafted as a single piece or in a two-part configuration. In the latter, the top is fabricated from alloy steel with threads, and the bottom from mild steel affixed to the frame. These two sections are threaded together and subsequently welded for added strength.

The carcass is embedded with diamond particles from the matrix, created using specific sizes of cemented carbide powder combined with an appropriate fusible metal binder, then pressed and sintered. The form of the carcass, specifically its working profile, encompasses the geometry of the working surface and the dimensions of the working area, tailored to suit various lithologies.

The steel body drill bit is crafted from alloy steel, shaped on a multi-axis lathe, and then welded to the joint. The matrix body drill bit is formed by sintering a combination of body powders and metal frames in a mould at temperatures ranging from 1,000 to 15,000 degrees before being welded to the joint.

Steel body bits are optimized for rapid drilling in formations that lack gravel and exhibit low compressive strength.

Matrix body bits are engineered for demanding formations characterized by high gravel content and robust compressive strength, inherently boasting superior resilience over steel body bits.

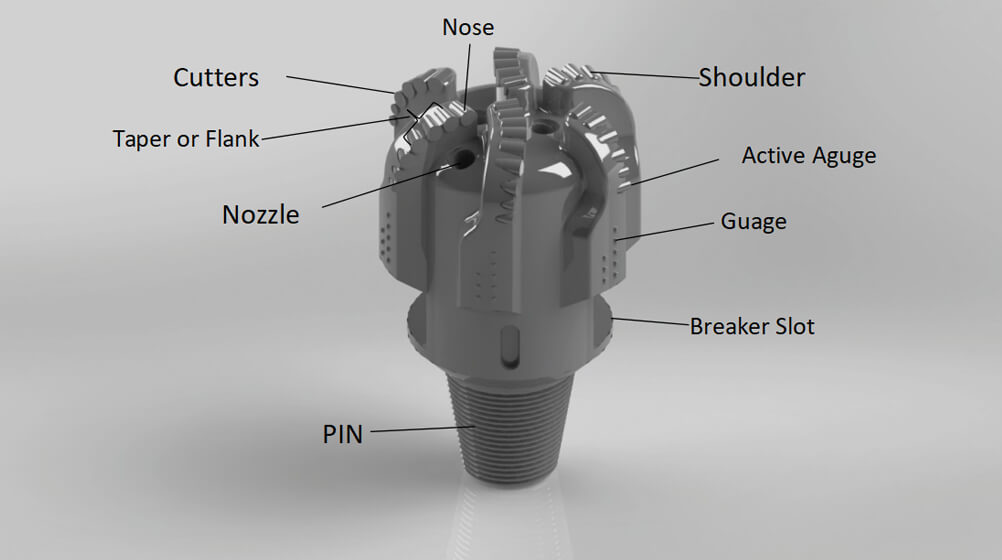

Polycrystalline Diamond Compact (PDC) bits, recognized for their rapid drilling capacity, enhanced durability, and economical efficiency, have become indispensable within the drilling sector. For detailed pricing inquiries, please liaise with Suburb Tools. Their predominant applications encompass:

1. Geological Exploration: Tailored for drilling within soft to medium-hard geological formations.

2. Coalfield Extraction: Specifically designed for drilling in coal seams, particularly in sedimentary rock strata.

3. Petroleum and Natural Gas Drilling: Imperative for the exploration processes in the hydrocarbon industry.