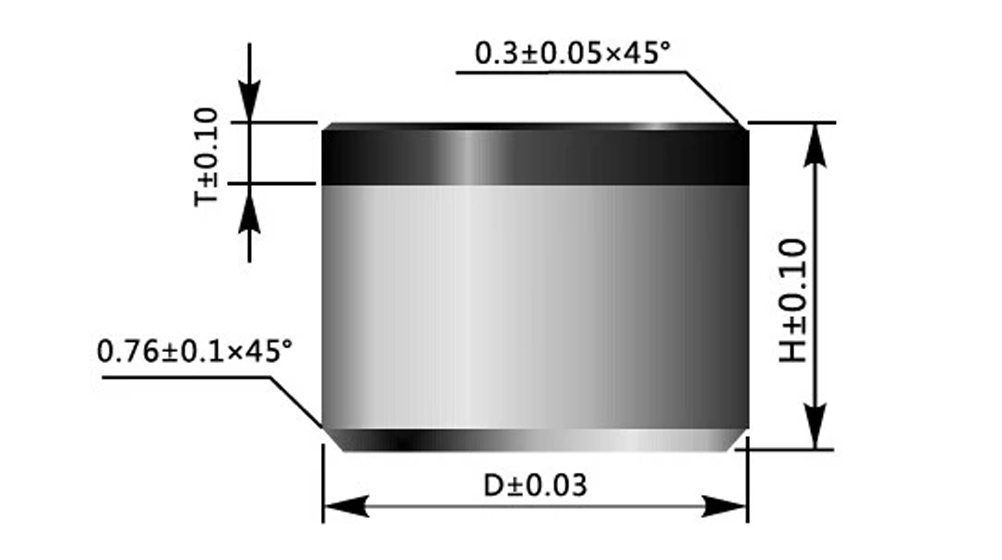

The artificial PDC cutter, crafted from polycrystalline diamond integrated with a carbide matrix, combines diamond's inherent hardness and thermal conductivity with carbide's strength and resilience. Leveraging diverse tooth configurations and specialized post-processing techniques, it effectively reduces residual stress, ensuring a robust interface bond, yielding unparalleled thermal stability and impact toughness.