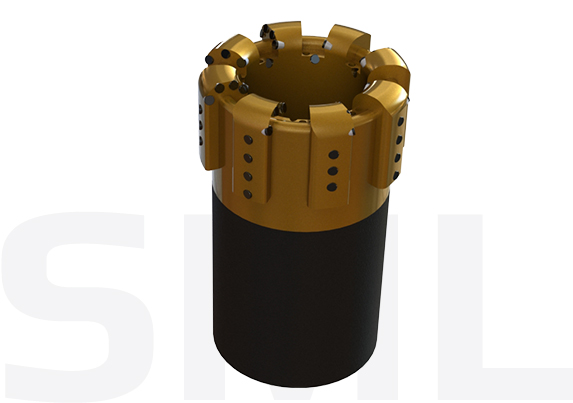

PDC Core Bits are made of high grade diamond single crystal or natural diamond particles, which are processed by scientific formula and special technology, and are designed for extra hard rock.

PDC Core Bits have high drilling speed and high efficiency, good diameter retention, high wear resistance and longer life.

PDC Core Bits can be used in coal mines, highways, railroads, bridges, geological exploration, water conservancy and hydropower, and other construction units.

PDC Core Bit is made of high grade diamond single crystal or natural diamond particles, processed by scientific formula and special technology, which is designed for extra hard rock.

PDC Core Bit has the characteristics of high speed and high efficiency, good diameter preservation, high wear resistance and longer life.

PDC Core Bits are widely used. From very soft to very hard strata, there are various series of diamond coring bits available to meet the needs of coring under various conditions.

The PDC Core Bit produced by SML has smooth drilling, fast speed, high harvest rate, long service life and good overall economic benefits.

Good size-preserving effect: SML produces Core Bits with high wear resistance and good size-preserving performance, which enable the cutting teeth to be used efficiently.