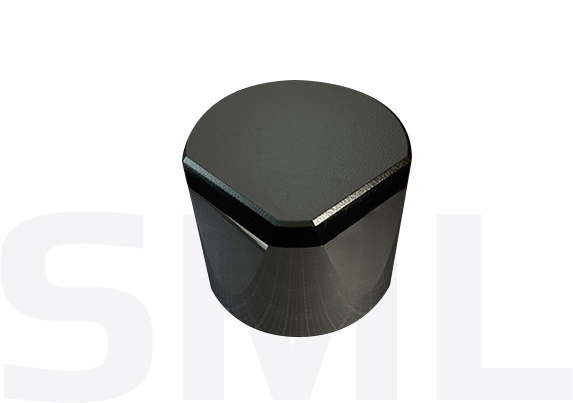

Precision Stability: The Shaped PDC Cutter expertly stabilizes bottom-hole vibrations, ensuring smooth operations.

Diverse Applications: Perfect for non-metals, non-ferrous metals, high-hardness alloys, wood, and ceramics. A true multi-material solution.

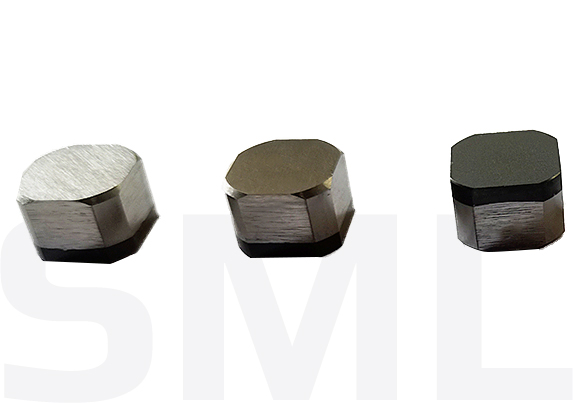

Customizable Designs: Choose from various shapes – rectangles, triangles, or fan designs – tailored to fit your specific needs.

Durability Meets Precision: Renowned for their high hardness, wear resistance, and accurate cutting capabilities.

Efficiency Amplified: Top Tool's drill bits with shaped teeth revolutionize soft rock drilling, mitigating diamond composite slippage.

OEM Ready: Looking for specialized drilling solutions? We offer OEM PDC bits to meet your unique requirements.

Cutting-Edge Tech for Soft Rock: Overcome common challenges in soft rock formations with Top Tool’s innovative drill bit designs.